Mix & Match

All Screws

Locking

►Increase Screw Size to Increase Strength

►Replace a 2.7mm or 3.5mm with a Larger Screw to Rescue Stripped Bone

►Better Accommodate Complex Fractures & Small Fragments with a 2.7mm

►Better Avoid Joints, Pins & Fracture Lines with Custom Screw Size

AO/ASIF

►Use Cortical or Cancellous Screws to Align Bone Before Locking Into Place

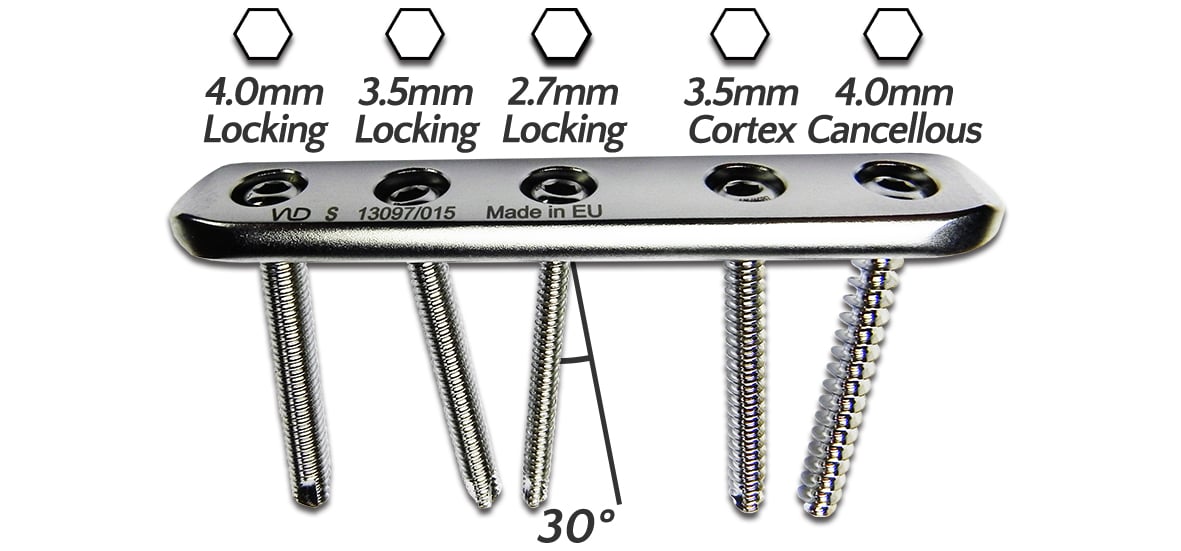

Different Core Diameter, Same Head Diameter

All ULS locking screws have equivalent head diameter and thus can be used with any locking plate. This permits the variation of multiple screw core diameters on a single plate while preserving full locking functionality. Surgeons can choose to increase core diameter to maximize shear and bending strength when more bone is available as well as decrease core diameter to lock small bone fragments into place. Additionally, surgeons can now rescue stripped bone by increasing screw size.

Align Bone & Optimize Compression

The ULS locking hole is also engineered to exhibit superior mechanical performance for stability with the application of AO cortical screws and AO cancellous screws. This dynamic design flexibility allows surgeons to better control load distribution and alignment of fixation for locking systems by 'pulling' bone into place before securing position with locking screws.

Polyaxial

Freedom

►Utilize Optimal Bone Diameter

►Avoid Joints, Pins & Fracture Lines

►Better Accommodate Comminuted Fractures & Small Bone Fragments

►Combine Monoaxial and Polyaxial Insertion to Create Varied Load Vectors to Protect Against Pull-Out

Each Patient is Unique

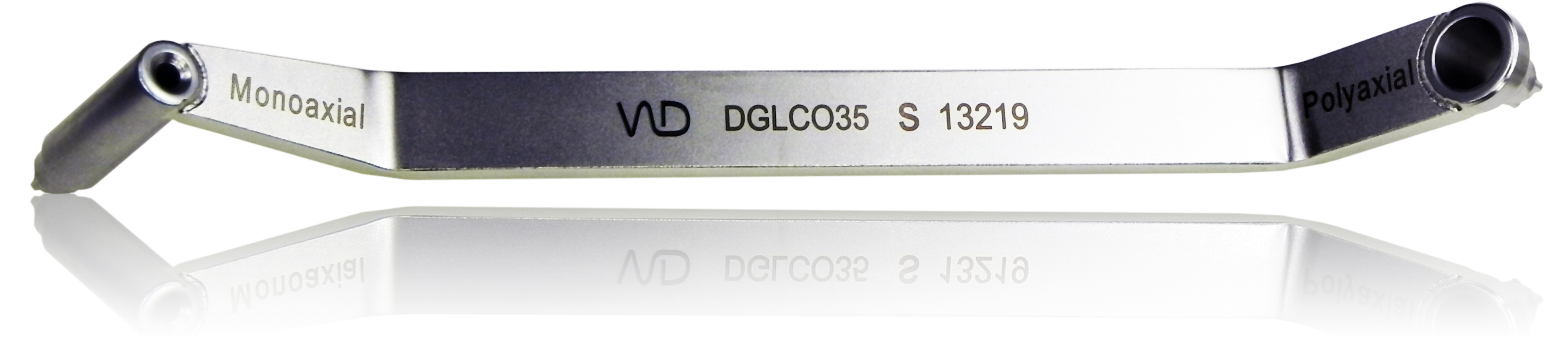

The universal locking system takes advantage of both monoaxial and polyaxial mechanisms for maxiumum control. Surgeons can utilize direct thread monoaxial locking for robust stability and easy screw removal while having the option for angulation when needed.

The ULS polyaxial locking mechanism is stable up to 30° (15° in every direction) and utilizes precision cross thread technology which is enhanced by the plate’s surface treatment and reliable for repeated insertion of the screw. You also have the option to minimize the risk of pullout failure by combining Monoaxial and Polyaxial insertion to vary the direction of load transfer and decrease potential stress risers at the bone-implant interface when parallel forces are applied.

The universal locking system takes advantage of both monoaxial and polyaxial mechanisms for maxiumum control. Surgeons can utilize direct thread monoaxial locking for robust stability and easy screw removal while having the option for angulation when needed.

The ULS polyaxial locking mechanism is stable up to 30° (15° in every direction) and utilizes precision cross thread technology which is enhanced by the plate’s surface treatment and reliable for repeated insertion of the screw. You also have the option to minimize the risk of pullout failure by combining Monoaxial and Polyaxial insertion to vary the direction of load transfer and decrease potential stress risers at the bone-implant interface when parallel forces are applied.

Quick-Connect

Drill Guides

►Instant Connection Drastically Reduces Extra Steps During Surgery

►Minimal Specialized Instrumentation (3 Combination Guides)

►Reliable Connection After Contouring a Plate

►Less to Sterilize, Clean & Manage

Eliminate the Redundancy of Threaded Guides

Screwing in and out threaded drill guides for every locking screw is repetitive and can significantly increase surgery time; furthermore, plate threads are susceptible to deformation from contouring. Each VID combination drill guide not only fits every plate, but also features a quick-connect interface that allows secure connection immediately. Surgeons can also utilize Monoaxial or Polyaxial insertion on a single guide and its geometry inherently exhibits superior resistance to deformation when contouring so you have superior connection reliability.

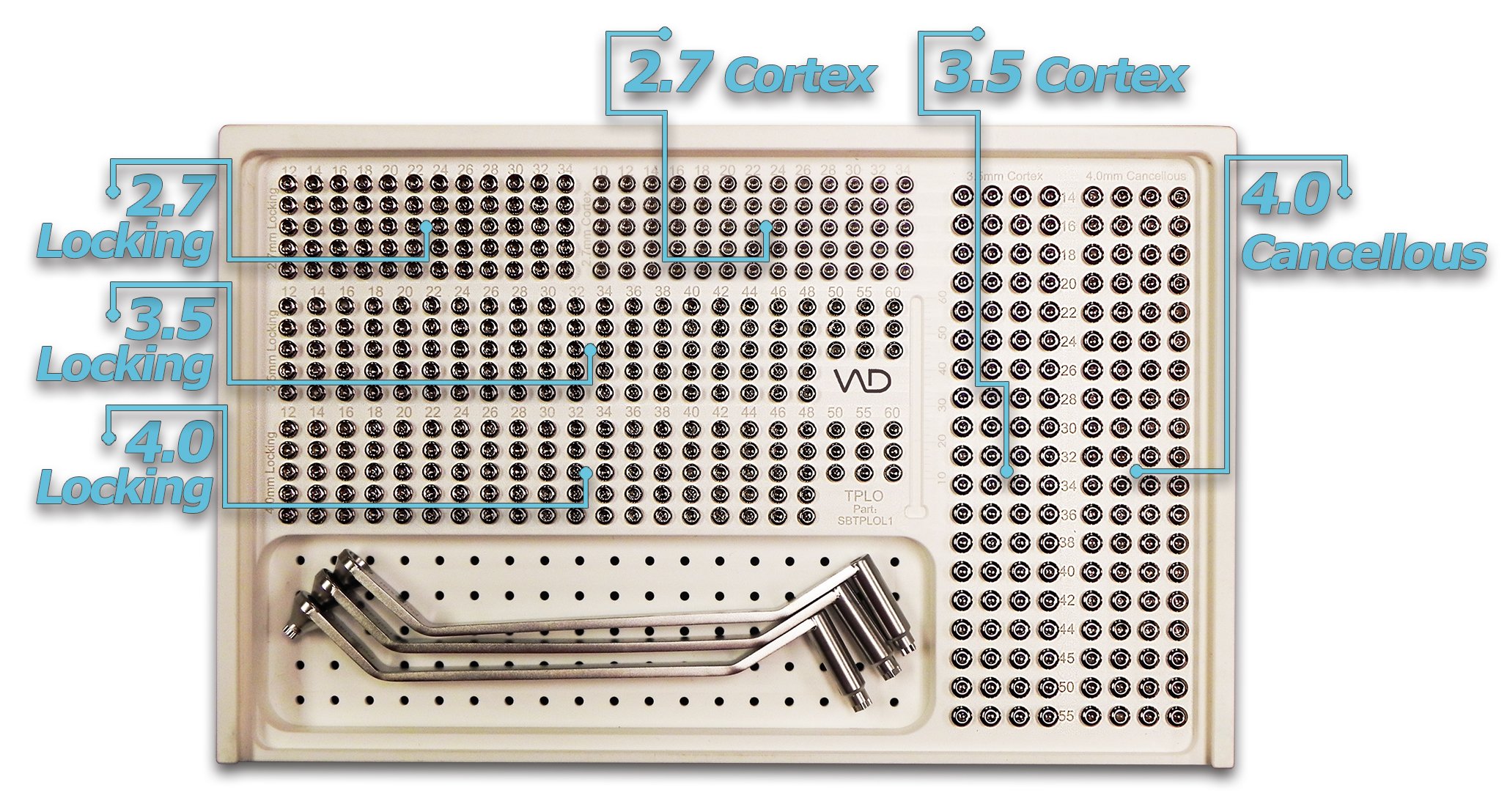

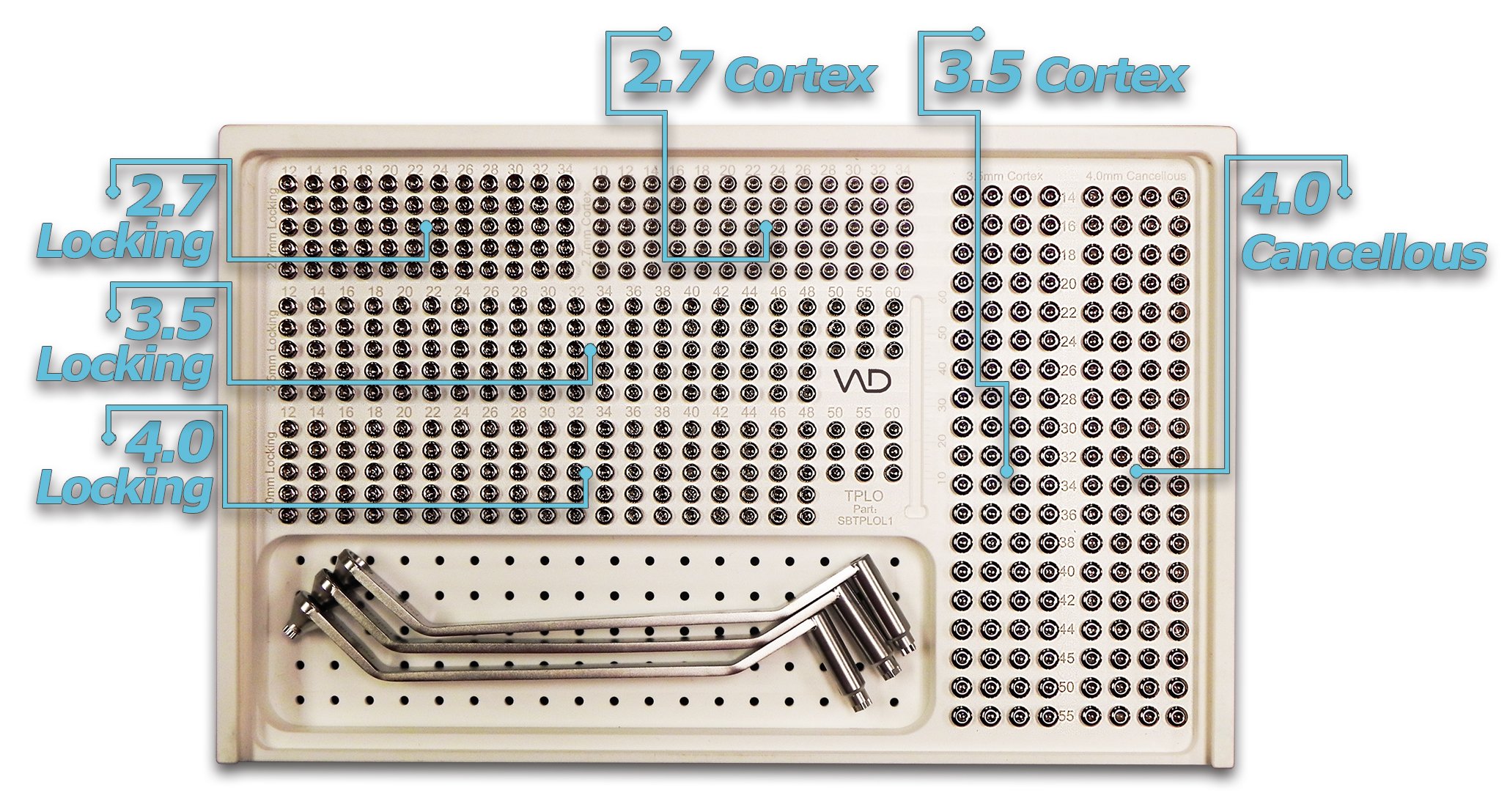

Everything in One Box

Locking + Non-Locking + Instruments + Plates

Locking + Non-Locking + Instruments + Plates

►Work out of One Box in the OR

►Enhance Organization

►268 Locking Screws (2.7mm, 3.5mm, 4.0mm)

►141 Cortical Screws (2.7mm, 3.5mm)

►80 Cancellous Screws (4.0mm)

►3 Drill Guides (2.7mm, 3.5mm, 4.0mm)

►Instrument Bay for Drill Bits & Plates

The Ideal TPLO

►Angle Away From the Joint When Needed

►Increase Locking Screw Size to 4.0mm for Maximum Strength

►Pay Less for Superior More Efficient Locking Screws

►Save Time in the OR with Quick-Connect Drill Guides

►Use AO Cortical Screws or Locking Screws in Every Plate

►Use One Box for Your TPLO

The Ideal TPLO

►Angle Away From the Joint When Needed

►Increase Locking Screw Size to 4.0mm for Maximum Strength

►Pay Less for Superior More Efficient Locking Screws

►Save Time in the OR with Quick-Connect Drill Guides

►Use AO Cortical Screws or Locking Screws in Every Plate

►Use One Box for Your TPLO

Do More with Your Locking Kit

►Mix & Match Your Screws

►Polyaxial up to 30°

►Quick-Connect Drill Guides

►All-in-One Sterilization Box

►Less Instrumentation

►More Affordable